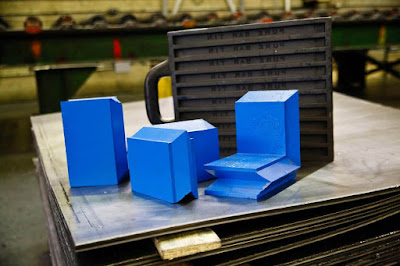

Lead is one of the best materials used in radiation protection. Interlocking lead bricks offer outstanding features and benefits because of their versatility. They are available in a wide range of standard and custom sizes, including corner units.

Lead is the leading material for radiation attenuation because of the high density and high atomic number of lead. Radiation shielding effectiveness is based on the density of the shielding material, its resistance to damage, its thermal properties, its cost and availability and, most importantly, its radiation attenuation effectiveness. Lead is a material that meets all these criteria. Lead is effective at blocking gamma rays, x-rays, and other types of nuclear radiation. But the specific use of lead in the form of interlocking lead bricks is especially invaluable because of their flexibility of use in the field of radiation shielding/protection. Here’s why:

A major advantage of using interlocking lead bricks for radiation protection is the dual benefit of the intrinsic properties of lead as a radiation barrier and the flexibility of use for this form of lead. Other lead shielding materials commonly in use are: lead clad building materials, lead laminated panels, lead sheet and foil, and even lead glass, to name some of the more popular forms.

Read original content...

Contact Details:

Canada Metal North America

8271 Lafrenaie, Montreal,

Quebec , Canada

H1P 2B1

Phone No: 1 800 363-7110

Email: contact@canadametal.com